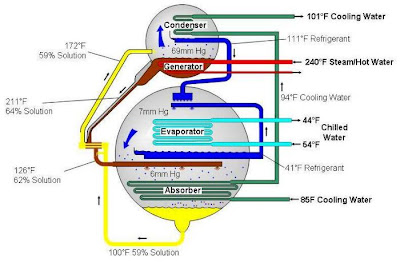

Absorption chiller occupies vital position in an HVAC system.Absorption

chiller is an equipment which uses a heat source, a refrigerant and an

absorbent for producing chilled or hot water. In the types of chillers,along with vapor compression water chiller or electric chiller ,absorption cooling system is also used in many applications.Absorption chillers produce chilled

water under vacuum conditions for the purpose of air-conditioning and

technology process.

Basic components of Vapor absorption chillers

Absorption

chillers in its simplest form (single stage) consist of following main parts:

|

| Steam absorption chiller |

- Generator

- Condenser

- Evaporator

- Absorber

- Heat exchanger

- Refrigerant Pump

- Solution pump

Working Principle of Absorption Chiller

1. Function of Generator in absorption chiller

In generator of absorption chillers weak solution is heated by operating

steam (steam absorption chillers),hot water or flue gases in indirect fired absorption chillers.While direct

fired absorption chillers are Natural gas, Diesel or Kerosene Oil Operated.After

heating in generator solution is concentrated and high temperature refrigerant

vapors are produced.After generator process in a chiller high temperature and pressure refrigerant vapors travel to condenser. A strong solution enters absorber through heat exchanger

in exchanging heat with weak solution .

2. Function of Condenser in absorption chiller

|

| vapor absorption cycle |

Refrigerant

vapor from generator is condensed in condenser by cooling water.Condensation is constant pressure process where refrigerant (water) gives off its heat to cooling water .In this way

refrigerant heat is carried to atmosphere.In water cooled chillers , cooling

water recycles after exchanging heat with air in cooling towers of same HVACsystem.

3. Function of Evaporator in absorption chiller

Refrigerant from condenser flows to

evaporator .In this compartment of absorption chiller,refrigerant gets

vaporized by taking heat from chilled water.Refrigerant from evaporator

refrigerant pan is pumped over the evaporator tubes with the help of

refrigerant pump.Flow of refrigerant over evaporator tubes evaporates the

refrigerant thus producing refrigeration effect, and evaporates to form vapor

by absorbing heat of chilled water flowing through tubes.In this way,evaporation takes place at constant pressure process where refrigerant gets latent heat from chiller water.Chiller absorption takes place here in absorber.Chilled water is cooled and return to the

system of customer.

4. Function of Absorber in

absorption chiller

Produced refrigerant vapor enters absorber, and absorbed by

strong solution in the absorber.In this way,strong solution is diluted by absorbing

refrigerant vapor in absorber . Heat generated is carried to atmosphere by

cooling water.

5. Function of HVAC Solution Pump in absorption chiller

This weak solution is transferred by solution pump

to generator for concentration.Pumps are components in absorption cooling systems which require electric energy for its operation.Weak solution from the absorber is pumped into

the generator through heat exchanger. This process is continued, and

refrigeration effect is repeated.

Must Read :

Absorption Chillers vs Electric (Compression) chillers

Try here HVAC quiz related to absorption chillers or vapor compression cycle.