What is a Pinch Valve

Relatively inexpensive linear motion pinch valve consists of a

flexible tube (rubber tubing) that is mechanically pinched from the outside of

the valve body. Pinch valves are suitable for on-off and throttling services.

However, the effective throttling range is usually between 10% and 95% of the

rated flow capacity. Pinch valves are ideally suited for the handling of slurries,

liquids with large amounts of suspended solids, and systems that convey solids pneumatically.

Because the operating mechanism of valve is completely isolated from the fluid, these

valves also find application where corrosion or metal contamination of the

fluid might be a problem.

|

| Pinch Valve |

The principal advantages of this type of valve are

that the flow passage is straight without any crevices, and there are no

internal moving parts. Pinch valve media are isolated from the working parts.

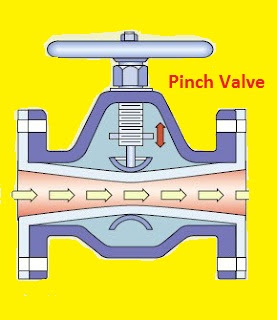

The pinch control valve consists of a sleeve molded of rubber or other

synthetic material and a pinching mechanism. All of the operating portions are

completely external to the valve. The molded sleeve is referred to as the valve

body. Pinch valve bodies are manufactured of natural and synthetic rubbers and

plastics which have good abrasion resistance properties. These properties permit little damage to the valve

sleeve, thereby providing virtually unimpeded flow. Sleeves are available with

either extended hubs and clamps designed to slip over a pipe end, or with a

flanged end having standard dimensions.

Pinch valves have molded bodies reinforced with

fabric. Pinch valves generally have a maximum operating temperature of 250oF.

At 250o F, maximum operating pressure varies generally from 100 psig

for a 1-inch diameter valve and decreases to 15 psig for a 12-inch diameter

valve. Special pinch valves are

available for temperature ranges of -100oF to 550oF and

operating pressures of 300 psig. Most pinch valves are supplied with the sleeve

(valve body) exposed. Another style fully encloses the sleeve within a metallic

body. This type controls flow either with the conventional wheel and screw

pinching device, hydraulically, or pneumatically with the pressure of the

liquid or gas within the metal case forcing the sleeve walls together to shut

off flow. Most exposed sleeve valves have limited vacuum application because of

the tendency of the sleeves to collapse when vacuum is applied. Some of the

encased valves can be used on vacuum service by applying a vacuum within the

metal casing and thus preventing the collapse of the sleeve.