Valves have some basic parts in common irrespective of the

type of valve.These basic parts of valves serve different functions during the

operation of valve.Understanding of basic parts of a valve practically helps plant operators and maintainers to perform their duties in a better way.

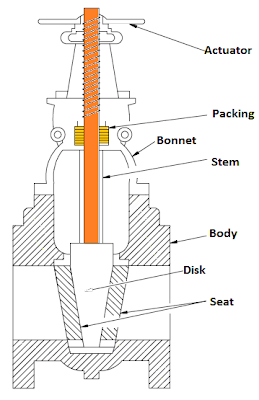

Following are the basic parts of a valve.

- Body of valve

- Bonnet of valve

- trim (internal elements) e.g Stem and disc ,seat and sleeve of valve stem

- actuator of valve

- packing of valve

1. Valve Body

Valve body, sometimes called the shell, is the primary

pressure boundary of a valve. It serves as the principal element of a valve

assembly because it is the framework that holds everything of valve together.

Body of valve has to withstand many forces inside the

valve.It is the first pressure boundary of a valve, resists fluid pressure

loads from connecting piping. Body of valve also experiences many forces due to

end connections of a valve. It receives inlet and outlet piping through

threaded, bolted, or welded joints.

|

| Basic parts of a valve |

The basic form of a valve body ranges from simple block

shapes to highly complex shapes in which the bonnet, a removable piece to make

assembly possible, form part of the pressure resisting body.

2. Valve Bonnet

Valve bonnet is basically the cover for the opening in the

valve body. In some designs, the body

itself is split into two sections that bolt together. Like valve bodies,

bonnets vary in design. Some bonnets function simply as valve covers, while

others support valve internals and accessories such as the steam, disk, and

actuator.

The bonnet of valve is second principal pressure boundary of a valve.

It is cast or forged of the same material as the body and is connected to the

body by a threaded, bolted, or welded joint.

In all cases, the attachment of

the bonnet to the body is considered a pressure boundary. This means that the

welded joint or bolts that connect the bonnet to the body are

pressure-retaining parts.

Bonnets of valves can complicate the manufacture of

valves, increase valve size, represent a significant cost portion of valve

cost.Bonnets of valves are a source for potential leakage.

3. Valve Trim

The internal elements of a valve are collectively called

as valve’s trim. The trim typically

includes a disk, seat, stem, and sleeves needed to guide the stem. A

valve’s performance is determined by the disk and seat interface and the

relation of the disk position to the seat. Contact of disk with seat matters

most when evaluating the performance of valves.Disk to seat contact determines

the presence of leakage from a valve.

Because of trim, basic motions and flow control are

possible. In rotational motion trim designs, the disk slides closely past the

seat to produce a change in flow opening. In linear motion trim design, the

disk lifts perpendicularly away from the seat so that an annular orifice

appears.

4. Valve Disk and Valve

Seat

For a valve having a bonnet, the valve disk is the third

primary principal pressure boundary. The valve disk provides the capability for

permitting and prohibiting fluid flow. With the disk closed, full system

pressure is applied across the disk if the outlet side is depressurized. For

this reason, the disk is a pressure-retaining part. Disks are typically forged

and, in some designs, hard-surfaced to provide good wear characteristics. A

fine surface finish of the seating area of a disk is necessary for good sealing

when the valve is closed. Most valves are named, in part, according to the

design.

The seat or seal rings provide the setting surface for the

disk. In some designs the body is machined to serve as the seating surface and

seal rings are not used. In other designs, forged seal rings are threaded or

welded to the body to provide the seating surface. To improve the

wear-resistance of the seal rings, the surface is often hard-faced by welding

and then machining the contact surface of the seal rings. A fine surface finish

of the seating area is necessary for good sealing when the valve is closed.

5. Valve Stem

Valve stem

connects the actuator and disk for positioning the disk in accordance with requirement. Stems

are typically forged and connected to the disk by threaded or welded joints.

For valve designs requiring stem packing or sealing to prevent leakage, a fine

surface finish of the stem in the area of the seal is necessary. Typically, a

stem is not considered a pressure boundary part.

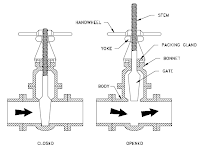

Two types of valve stems are rising stems and non-rising

stems. These two types of stems are easily

distinguished by observation.

For a rising stem valve, the stem will rise above

the actuator as the valve is opened.

This occurs because the stem is threaded

and mated with the bushing threads of a yoke that is an integral part of, or is

mounted to, the bonnet.

There is no upward stem movement from outside the valve

for a non-rising stem design. For the non-rising stem design, the valve disk is

threaded internally and mates with the stem threads.

6. Valve Actuator

Valve actuator operates the stem and disk assembly. An

actuator may be manually operated hand wheel, manual lever, motor operated,

solenoid operated, pneumatic operated, or hydraulic operated.Valve actuator

basically directs the disc to open ,close or throttle depending upon the type of valve.

7. Valve packing

Valve packing prevent leakage from the space between the

stem and the bonnet. Valve Packing is commonly graphite ring, fibrous material

(such as flax) or another compound (such as Teflon) that forms a seal between

the internal parts of a valve and the outside where the stem extends through

the body.

Valve

packing must be properly compressed to prevent fluid loss and damage to the

valve’s stem. If a valve’s packing is too loose, the valve will leak, which is

a safety hazard. If the packing is too tight, it will impair the movement and

possibly damage the stem.

No comments:

Post a Comment